The conversation on what circular economy is and why it matters in a sustainability journey has been ongoing since governments and companies worldwide started pledging to achieve net-zero emissions of greenhouse gasses no later than 2050Source: Shutterstock

What is a circular economy? The world’s largest PC maker explains

- Tech Wire Asia speaks to Mary Jacques about what a circular economy is.

- Mary also shares how the company has increased its participation in the circular economy.

The conversation on what circular economy is and why it matters in a sustainability journey has been ongoing since governments and companies worldwide started pledging to achieve net-zero emissions of greenhouse gasses no later than 2050. In fact, more businesses today are actively shifting from a linear “take, make, waste” economy to a circular “reduce, reuse, recycle” one.

Take the world’s largest distributor of personal computers (PCs), Lenovo, for instance. Throughout the years, the global technology powerhouse has expanded its product and service lines and increased its participation in the circular economy.

“The economic advantages of employing a circular model in the E&E sector could be enormous. A circular economic model in IT could reduce costs for consumers by 7% in 2030 and 14% by 2040,” Lenovo said in a whitepaper.

First, what is a circular economy?

Mary Jacques, Director ESG and Principle Engineer on Lenovo’s pioneering efforts to create technology that is more sustainable, using innovation to light the way to a smarter, more sustainable future.

The circular economy is one of the hottest topics in sustainability today. According to the Circularity Gap Report 2023, rising material extraction has shrunk global circularity: from 9.1% in 2018 to 8.6% in 2020 and now 7.2% in 2023. That leaves a vast circularity gap – meaning more than 93% of materials are wasted, lost, or unavailable for reuse for years.

To bring human activity back within the safe limits of the planet, the report estimates that we would need to reduce global material extraction and consumption by one-third. That is when the circular economy comes into play. It is a system of producing and consuming products in which resources are kept within the ecosystem to prevent or significantly reduce waste.

As such, the circular economy is a production and consumption model involving sharing, leasing, reusing, repairing, refurbishing, and recycling existing materials and products as long as possible.

How is Lenovo contributing to the circular economy?

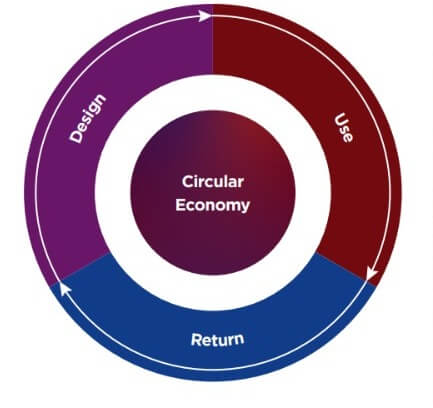

Lenovo’s vision to deliver smarter technology for all extends to its circular economy practices, including smarter circular design, circular use, and circular return activities. That means that during the design phase, important decisions are made to help improve circularity, whereby the company continuously evaluates design decisions that can help reduce environmental impact.

“At Lenovo, we think about sustainability in terms of ESG, especially in the last five years. In the environmental space, we’re focused on climate change and the circular economy. From a climate change perspective, it’s our operations and the impact of our value chain. The circular economy especially is a big focus – making sure our products can be repaired and kept in service for a long time,” Mary Jacques, executive director of global ESG and regulatory compliance at Lenovo, told Tech Wire Asia.

Jacques shared how new recycled materials are constantly researched and introduced into Lenovo’s products. “We continue to incorporate post-industrial recycled content (PIC) plastics, post-consumer recycled content (PCC) plastics, and closed-loop post-consumer recycled content plastics (CL PCC) to introduce new materials such as ocean-bound plastics (OBP) and recycled metals.”

Lenovo has been using recycled plastics in products since 2008 and is on track to employ over 136 million kilograms of PCC plastic by FY 2025/26. “We now manufacture 248 products that include closed-loop recycled plastic,” Jacques shared. At the same time, Lenovo has also been increasing its use of recycled fiber, recycled plastic, and sustainable materials in packaging, including bamboo, sugarcane, and sustainably forested fiber.

What is circular economy for Lenovo? It is innovating packaging by incorporating compostable sugarcane and bamboo while phasing out Styrofoam and plastic.

Source: Lenovo’s Twitter

“We have a goal that by FY 2025/26, 90% of plastic packaging will be made from recycled plastics for notebook computers, desktop computers, and workstation computers. Additional goals for smartphone product packaging include 60% of the materials will be recycled content, and single-use plastics will be reduced by 50% by FY 2025/26,” Jacques said.

She also shared first-hand how Lenovo’s focus on repairability and durability contributes to the prolonged life cycles of refurbished and reused systems, creating opportunities throughout the circular value chain. Specifically, the goal is that by FY 2025/26, 84% of repairs can be done at the customer site without having to send their PC to a service center. The company is also keeping repairable parts in use longer and has a goal that by FY 2025/26, at least 76% of repairable parts will be repaired for future use.

What is the circular economy for Lenovo? It is practices that include Smarter Circular Design, Smarter Circular Use, and Smarter Circular Return activities.

Source: Lenovo’s ESG Report 2022/2023

What sort of partnership is involved in Lenovo’s circular economy?

Lenovo’s circular value chain involves partnerships at every phase, according to Jacques. “In the design phase, we must partner with materials suppliers for our products and packaging sourced from recycled materials or used IT equipment. Then there’s the use phase, where we partner with our customers to ensure that we understand their needs regarding services and repairing the products.”

At the end of a product’s life, since Lenovo is not a recycler, Jacques shared that they would connect customers to responsible recycling in a way that helps extract the most value out of the products at the end of life. “And so throughout that whole circle, there are critical partnerships we must have because we can’t do it all on our own,” she concluded.

READ MORE

- 3 Steps to Successfully Automate Copilot for Microsoft 365 Implementation

- Trustworthy AI – the Promise of Enterprise-Friendly Generative Machine Learning with Dell and NVIDIA

- Strategies for Democratizing GenAI

- The criticality of endpoint management in cybersecurity and operations

- Ethical AI: The renewed importance of safeguarding data and customer privacy in Generative AI applications