How to achieve operational efficiency in your supply chain

NOT SINCE the standardization of international shipping containers by the International Maritime Organization in the late 1960’s has the logistics industry seen such changes as it is now experiencing.

It is an oft-repeated trope on this site that technology is causing seismic upheavals. In this particular instance, the changes wrought by tech have not all emanated from the logistics industry itself, but rather, it’s changes in customer and supplier behavior too, which have changed the world.

Consumers now expect to make purchases through multiple channels, and demand ultra-prompt delivery. Wholesalers are having to change tack as some manufacturers bypass the wholesale distribution channel altogether. And vendors are demanding a just-in-time supply model to keep inventory catalogs to a minimum.

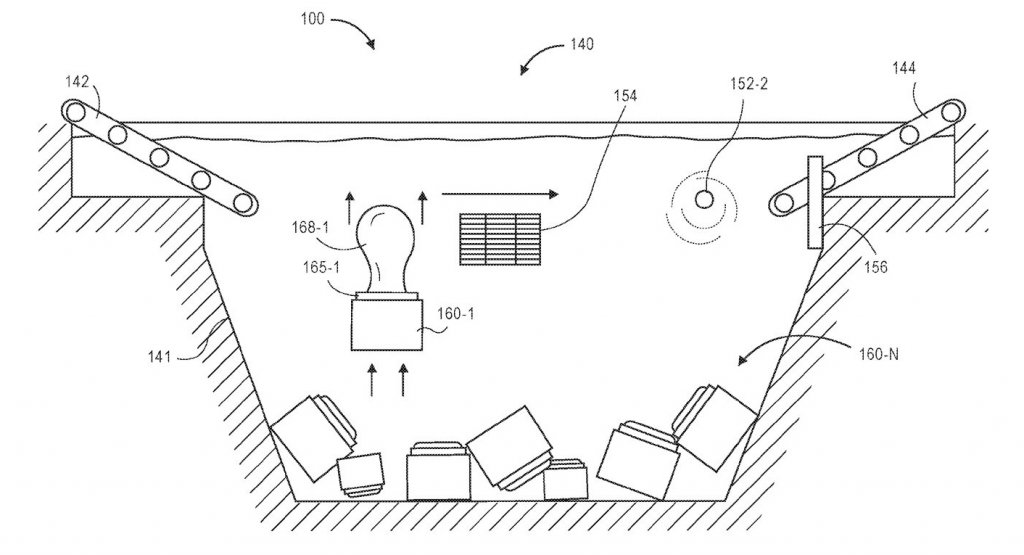

Some key players are coming up with innovative solutions to improve their own efficiencies. The infamous example of Amazon’s patent application for underwater storage centers made some headlines, and that self-same company holds annual competitions to see if robotics can be better employed in its fulfillment centers.

Amazon’s patent for underwater storage facilities. Source: US Office of Patents

But while separate elements in the supply chain are beginning to assimilate the benefits that the latest technologies can offer, the fact remains that across the supply chain, data exists in disparate areas; so-called data silos.

In addition to electronically-held data, manual information chains still abound, as often very different industries each play their part in the end goal of satisfying demand for goods: from e-commerce giants to rickshaw delivery drivers.

When a ship arrives in a port, for instance, there is in all likelihood no way that the person or organization that placed an order for a consignment can be immediately aware of the fact that a significant waypoint has been reached. That is, not aware without traditional paperwork being filled out, probably entered manually into Excel sheets somewhere, then emailed, cross-correlated against a database or two, and so forth.

In order that true efficiencies can be achieved, and in order that demand for up-to-the-minute tracking data can be satisfied, the logistics service provision sector (and increasingly the retail and manufacturing sectors) needs a “single source of truth” (to borrow a term from business intelligence system jargon).

The barge Columbia Elizabeth arrived at the San Juan #PuertoRico port Nov. 24th with 350+ wooden poles, measuring 65 and 70 feet in length. Logistician Andre Baker talks about the logistics behind moving the poles. ?: CPT R. Hignight, M. Izard-Carroll pic.twitter.com/3C73ztKdai

— USACE HQ (@USACEHQ) November 26, 2017

The movement of goods across the world is as old as commerce itself, and therefore the logistics industry has deep roots; roots that should not be torn up simply in the name of progress. In technology terms, software and hardware systems have grown up that have allowed modern trade routes and methods to develop. Those systems are relied upon.

Legacy systems, therefore, cannot be discounted, but the silo-ing of data is a problem that consumers and fulfillers are demanding to be solved: we all now expect that trans-continental shipping is as seamless and transparent as a local parcel delivery.

Therefore, retailers, manufacturers, and logistics concerns are looking for technology solutions which not only will deliver according to the absolute latest expectations but will integrate with older systems that already handle data well and efficiently, albeit within a particular niche in the entire supply chain story.

Additionally, the availability of so-called big data can and should be gainfully employed. Up-to-the-minute weather reports inform organizations’ expectations of consignment arrival and departure times. Local politics, social and political changes and financial fluctuations all have their effects, but it’s difficult to collate the mass of data that’s out there, cross-correlate the data that is available and run a profitable business too!

There are several technology specialists in today’s market that hope to address the need for greater efficiency and visibility right across the supply chain. Here are four which we at Tech Wire Asia consider worth your attention.

The Hong Kong-based Gravity Supply Chain offers a cloud-based solution to logistics organizations, as well as retailers and manufacturers.

The company’s offerings are three-fold, with different levels of their application available according to need and requirements. The company’s vision is that its online solution “wraps around” existing supply chain technology systems, and, where necessary, fills in the gaps between disparate systems.

It achieves this by allowing all available data from legacy installations to flow into its centralized services and ensuring disparate data streams are presented and processed via one interface.

Gravity’s user experience is simple and effective using dashboards and tiles to organize data and enable users to drill down for more detail.

Gravity Supply Chain comes pre-configured with thousands of schedules for air freight and sea carriers: it is estimated that some companies’ operators spend up to 30 percent of their time simply looking up schedules manually!

As well as utilizing third-party legacy systems (which it can if required, replace), and providing its own data solutions, the offering also pulls in impactful information from a variety of other sources.

By examining local media, weather reports, social media feeds, political reports and financial market data, astute and relevant changes to up-to-the-minute information can be made.

Logility Voyager Solutions cover supply chain and logistics management in their entirety. From planning and forecasting, sourcing and production and through to transportation management, the software claims to save costs, increase efficiency and increase supply transparency.

The software is available as a cloud-based solution operating as a software-as-a-service provision (SaaS), or it can be hosted on-premises given the existence of in-house IT infrastructure and capability.

In addition to providing the technology, Logility also offers what is termed “optimization services”. These are the provision of an expert in logistics management systems who will evaluate clients’ strategies and advise across the board, on what is effectively a consultancy basis.

The expert will also be able to advise enterprises on the most effective way to use the Voyager solution, ensuring that clients get a maximum return on investment (ROI).

The individual aspects of Logility Voyager Solutions span demand, inventory, replenishment & supply planning and S&OP. For the retail end of the chain, the solution addresses manufacturing planning, retail merchandise planning, and assortment & allocation.

For legacy systems, the company’s Logility Voyager AdapLink uses templates, standardized connectors, and data transformations to ensure integration with systems like SAP, Oracle, Microsoft Dynamics and Infor goes smoothly.

Like many logistics and supply chain technology companies, OpenPort is based in Hong Kong. Traditionally the bridge between east and west has represented the best location to manage the international flow of goods.

In today’s world of interconnectivity, however, geographical location is not important. But HK’s legacy remains – the address on the company letterhead containing the autonomous territory still means that the company means global business.

OpenPort develops mobile logistics platforms for enterprise-level supply chains. Its platform connects shippers & carriers and enables consumer goods companies and local transporters to set rates, exchange services, and track performance under the umbrella of one over-arching solution.

The company offers dispatcher tools to send order instructions to drivers using a mobile app and there is also “Marketplace”, a tool for carriers to provide their services to multinational shippers on contract, and ad-hoc basis.

OpenPort’s solution is built on what it terms “blockchain-compatible architecture“, which ensures an unassailably transparent record: exactly when and who (and what) was involved with every shipment, every step of the way along the supply chain.

In a video published on PortTechnology.org, Blockchain Labs for Open Collaboration (BLOC)[https://un-bloc.com/leadership/] CEO Deanna MacDonald said:

“Whether we are talking about currencies or […] shipping containers, they are […] data points. When we put all those data points in one common repository that is accessible to everybody in a supply chain […], what you are creating is a commons for the exchange of trusted information between parties.”

While RELEX’s cloud-based software could be employed to improve an individual aspect or two of a concern’s supply chain operations, the company is increasingly concerning itself with a fully integrated, unified retail process management solution.

Some retail operators may use the software to, say, improve forecasting and replenishment, or better plan for staffing fluctuations. But, in order to achieve business-changing positive effects, the retail operation should be considered as a whole – from PO to invoice, from purchase to order fulfillment.

RELEX’s core market is in retailers and suppliers of merchandise with limited shelf-life. Here, despite the perishables’ market segment being infamously fickle, the biggest gains can be delivered by optimization via technology solutions. Waste reduction of up to 40 percent is but one proven possibility.

RELEX’s software can produce improvements right across the entire retail cycle – from procurement to shelf-life optimization, via ordering, logistics, warehousing, staffing and so on.

By planning activities that encompass the entire supply chain, gains can be made at every stage in a cascade effect. Stock levels, for instance, can be optimized based on the priority or role of each SKU in order to maximize sales and shelf availability.

And even physical stores’ layouts can be planned and experimented with. At a smaller scale, by feeding back in-store results, changes can percolate back up the chain.

READ MORE

- 3 Steps to Successfully Automate Copilot for Microsoft 365 Implementation

- Trustworthy AI – the Promise of Enterprise-Friendly Generative Machine Learning with Dell and NVIDIA

- Strategies for Democratizing GenAI

- The criticality of endpoint management in cybersecurity and operations

- Ethical AI: The renewed importance of safeguarding data and customer privacy in Generative AI applications