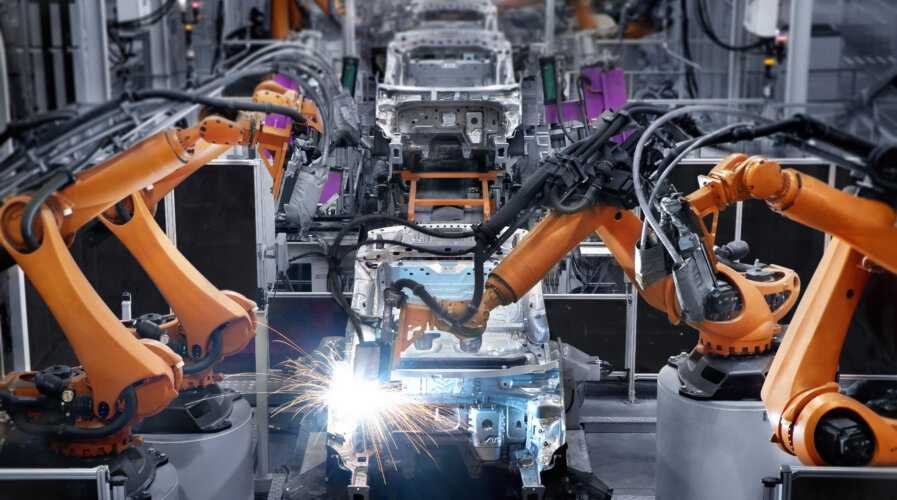

Kia and Boston Dynamics are set to launch a new robot in 2024. (Source – Shutterstock)

More robots in the future: Kia and Boston Dynamics set to launch a robot in 2024

- Kia and Boston Dynamics merge auto and robotics in an exciting, game-changing venture.

- Kia sets industry milestones with ambitious eco-goals and a forthcoming robot.

Kia, in collaboration with Boston Dynamics, an American robotics company acquired by Kia’s parent company, Hyundai Motor Group, in 2021, has plans to launch a new robot in 2024. This development was disclosed in the most recent sustainability report released by the South Korean automaker.

The report does not reveal specific details about the upcoming robot. Nonetheless, the automaker intends to capitalize on its existing expertise in manufacturing and production within the automotive industry to expand into areas such as robotics logistics and unmanned delivery services, thereby integrating cutting-edge robotics technology into its operations.

As per an official from the Hyundai Motor Group, the upcoming 2024 robot unveiling aligns with the company’s extensive efforts in robotics research and development. While Hyundai Motor Group is actively researching and developing different types of robots, there are no confirmed specifics about the robot set to be launched next year.

How can a robot change the industrial landscape? Look at Boston Dynamics

The decision to introduce a new robot resonates with the growing need for robotic applications across various sectors. Notable examples include Boston Dynamics’ Spot and Stretch robots, which are a safety robot and warehouse robot respectively, both commercially successful.

Spot has gained recognition as a prominent example of autonomous robotics, with applications spanning various industries like oil and gas, security, search and rescue, and even construction.

The capabilities of Spot have evolved, offering a customizable platform adaptable to diverse tasks and industries. It is equipped to integrate with a variety of sensors such as thermal cameras, lidar, and 3D imaging, enabling the creation of digital twins and offering predictive maintenance.

Stretch, although less familiar to many, was specifically designed to serve the logistics industry. It features a compact base that can move safely in any direction and navigate obstacles like ramps. Advanced computer vision is employed by a perception mast for quick and accurate case detection.

The distinguishing factor for Stretch is its specially built robotic arm, with seven degrees of freedom and an adaptive vacuum gripper. This arm, in conjunction with the perception system, manipulates a wide array of cartons. A high-capacity battery option allows Stretch to work through two full shifts, supporting continuous, flexible unloading.

Like other Boston Dynamics robots, Stretch provides support for monotonous, dirty, and risky tasks in manufacturing and warehousing.

Should these two robots not sound familiar, the video below, which went viral on social media, may jog your memory.

The details of Hyundai’s new robot are still under wraps, but the anticipation for its release underscores the growing relevance of robotics in the future development of various sectors.

Kia’s ambitious investment

Kia is set to invest approximately 28 trillion won ($21.9 billion) in advanced air mobility fields through 2026. The company is exploring electric vertical takeoff and landing aircraft (eVTOL), with plans to begin mass production by 2028 after conducting feasibility tests with prototype aircraft next year.

Under the newly adopted slogan, “Sustainable Movement for an Inspiring Future”, Kia has set ambitious targets, such as achieving zero carbon emissions by 2045. The report accentuates Kia’s commitment to ensuring 100 percent renewable energy use across its manufacturing facilities in South Korea, China, India, Mexico, Slovakia, and the United States by 2040, an important stride towards its environmental goals.

Kia is eager to expedite its shift towards an entirely electric future, with a goal to boast an all-electric vehicle lineup of 15 cars by 2027. As part of its larger sustainability strategy, the company is working towards raising the share of electric vehicle (EV) sales to 52 percent of total sales in major markets, including Korea, China, North America, and Europe, by 2030. With a focus on expanding EV production, Kia is looking to significantly cut down carbon emissions, thus contributing to a cleaner automotive environment.

The forthcoming Kia EV9, a large three-row sport utility vehicle, is powered by environmentally friendly electric batteries. The vehicle has a carbon emissions profile that is 23 percent lower compared to same-class vehicles with internal combustion engines.

The new Kia EV9 is powered by environmentally friendly electric batteries (Source – Shutterstock)

The new robot being developed by Kia, in partnership with Boston Dynamics, is a testament to the automotive industry’s evolving trend towards the integration of robotics and autonomous systems. It is anticipated to bring about significant improvements in industrial processes and efficiency, thereby potentially influencing the unmanned delivery services industry and redefining the automotive sector.

This robot could boost efficiency and productivity in the automotive industry, similar to Boston Dynamics’ Spot and Stretch. It has the potential to automate tasks like logistics, assembly, inspection, and maintenance, thereby reducing costs and mistakes and enhancing safety in challenging work environments.

Transforming the auto industry

The introduction of the robot is in line with the industry’s ongoing shift towards robotics, AI, and automation, contributing to faster production lines, more accurate assembly, and reduced waste. It could also be extended to areas such as vehicle testing, quality control, and post-sales services.

Moreover, Kia’s decision to explore robotics logistics and unmanned delivery services comes at a time when e-commerce is on the rise, and the demand for contactless deliveries is high. The new robot could play a crucial role in meeting these emerging needs by ensuring the efficient and prompt delivery of goods.

Kia’s alliance with Boston Dynamics marks a shift from conventional automaking to advanced mobility solutions, thereby enhancing service offerings and operations and promoting sustainability. Robots in auto production can increase efficiency, reduce costs, and improve safety, as they are capable of performing repetitive, precision tasks and operating under hazardous conditions.

Furthermore, as Kia broadens its range of electric vehicles, robots could prove invaluable in the production and assembly of batteries – areas where automation can have significant benefits. By increasing manufacturing efficiency, Kia’s sustainability goals could be achieved faster, influencing the broader automotive industry and paving the way for a more efficient, safer, and sustainable future.

READ MORE

- 3 Steps to Successfully Automate Copilot for Microsoft 365 Implementation

- Trustworthy AI – the Promise of Enterprise-Friendly Generative Machine Learning with Dell and NVIDIA

- Strategies for Democratizing GenAI

- The criticality of endpoint management in cybersecurity and operations

- Ethical AI: The renewed importance of safeguarding data and customer privacy in Generative AI applications